Denounce with righteous indignation and dislike men who are beguiled and demoralized by the charms pleasure moment so blinded desire that they cannot foresee the pain and trouble.

Read MoreNimonic 75 Supplier and Stockist in India

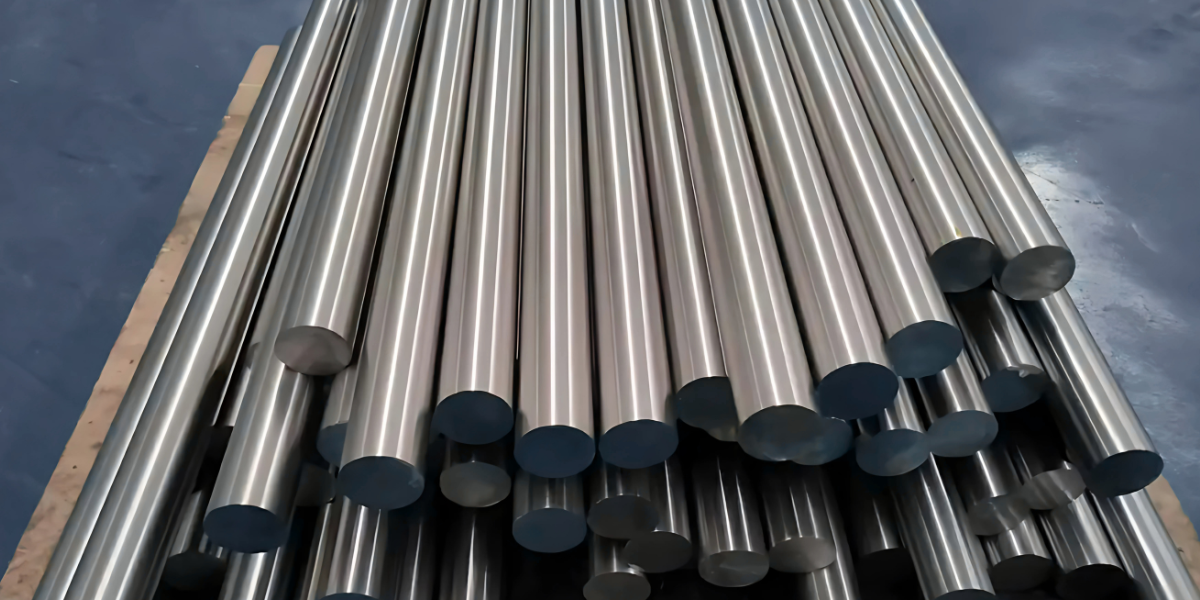

Largest Nimonic 75 Stockist in Mumbai, India. Nimonic 75 Sheets Distributor, ASTM B637 Nimonic 75 Round Bars Supplier, Nimonic 75 Plates Exporter. Reliable Aerospace Grade Nimonic 75 Supplier & Exporter in India.

Nimonic 75 (UNS N07075) is a nickel-chromium-cobalt alloy engineered for high-temperature strength, excellent creep resistance, and outstanding corrosion performance. With superior mechanical properties and thermal stability, it maintains its strength under extreme operating conditions, making it ideal for aerospace and defense applications such as turbine blades, combustion chambers, and high-performance engine components. Its combination of durability, oxidation resistance, and fatigue strength ensures reliable performance in mission-critical environments.

Nimonic 75 Stockist

At Bhansali AeroAlloys, we supply premium-quality Nimonic 75 round bars, sheets, plates, and custom forms designed to meet the demanding specifications of aerospace and defense sectors. Our commitment to precision, rigorous quality control, and timely delivery ensures materials that perform flawlessly in high-stress applications. For technical guidance, custom solutions, or pricing inquiries, reach out to our expert team today at sales@bhansaliaeroalloys.com and partner with a trusted supplier of advanced nickel-based alloys.

Specifications

- W.Nr: 2.4951

- W.Nr: 2.4630

- UNS: N06075

- AWS 032

- BS HR 5

- BS HR 504

Key Features of Nimonic 75

| Excellent corrosion resistance |

| Outstanding heat resistance |

| Suitable for high-temperature static applications |

Typical Applications of Nimonic 75

| Gas turbine engines |

| Industrial furnaces |

| Nuclear engineering |

Chemical Composition

| Element | Min % | Max % |

|---|---|---|

| C | 0.08 | 0.15 |

| Si | - | 0.30 |

| Mn | - | 1.00 |

| S | - | 0.015 |

| Co | - | 5.00 |

| Cr | 19.0 | 21.0 |

| Cu | - | 0.50 |

| Fe | - | 5.00 |

| Pb | - | 0.005 |

| Ti | 0.20 | 0.50 |

| P | - | 0.015 |

| Al | - | 0.40 |

| Ni | Balance | - |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.37 g/cm³ | 0.302 lb/in³ |

| Melting Point | 1380 °C | 2520 °F |

| Coefficient of Expansion | 11.0 μm/m·°C (20–100 °C) | 6.1 × 10⁻⁶ in/in·°F (70–212 °F) |

| Modulus of Rigidity | 75.6 kN/mm² | 10,965 ksi |

| Modulus of Elasticity | 206 kN/mm² | 29,878 ksi |

Heat Treatment

| Condition | Type | Temperature | Time (hrs) | Cooling |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 450 – 470 °C (840 – 880 °F) | 0.5 – 1 | Air |

Typical Mechanical Properties

| Condition | Approx. Tensile Strength | Approx. Operating Temperature |

|---|---|---|

| Annealed | <800 N/mm² | <116 ksi | -200 to +1000 °C | -330 to +1830 °F |

| Spring Temper | 1200–1500 N/mm² | 174–218 ksi | -200 to +1000 °C | -330 to +1830 °F |